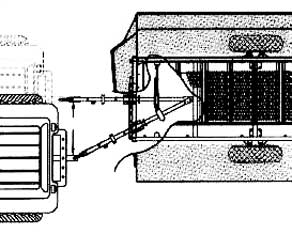

Gravity Flow With or Without Drum Regulator

The regulator is powered by an independently controlled, reversible, hydraulic motor which allows forward and reverse operations of the regulator, practically eliminating spills. Flowing cotton over the regulator will throw cotton to the far side of the builder; flowing cotton under the regulator will flow cotton to the near side. Even distribution of cotton in the module builder builds tighter and more dense modules with more cotton per module. These modules will resist weather damage and won’t break apart when moving.

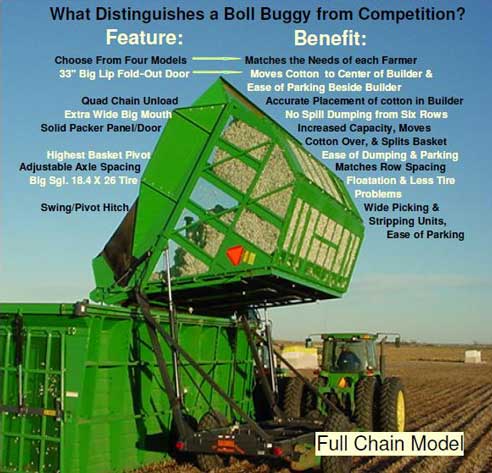

Choose From Four Models of Boll Buggys®

One to Match Every Cotton Farmer’s Needs

BB1

Gravity Side, Gravity Big Lip, No Metering

BB2

Gravity Side, Gravity BigLip, Drum Style Metering

BB3

Gravity Side, Chain Big Lip, Chain door Metering

BB4

Chain side, Chain Big Lip, Full Chain Metering

Your picker/stripper has a packing device, why not your Boll Buggy®?

The patented packer/divider panel performs two important functions. First, it compresses the initial dumps to 2/3 of their original size, increasing the overall capacity of the Boll Buggy® by as much as 33 percent. Second, it divides the buggy load into two parts and while dumping, holds half of the load in the top part of the buggy, avoiding flooding conveyor or regulator with too much cotton at one time. This allows the conveyor or regulator to smoothly and accurately meter the cotton into a module builder or trailer. This makes topping off a snap.

Packer/divider door not only packs, but moves the cotton over from the dump inside, to the dump outside, where your picker can’t reach. This is another increase in the overall capacity of the Boll Buggy®. Using the packer/divider door allows the dumping of two average sized four row dumps.

Adj. Axle Spacing

From the minimum wheel spacing of 120″, each wheel can be adjusted out 10″ or 16″. This makes it possible to provide more stability to the dump out side.

Example:

| Set wheels on dump in side out | 10″ |

| Set wheels on dump out side out | 16″ |

| +120″ | |

| Equals wheel spacing | 148″ |

This will fit 5 30″ rows but puts the tractor 1/2 row off. This can be remedied by using a swing hitch or adjusting the hitch and tractor drawbar to center the tractor back on row.

High Basket Pivot

12′ 6″ from ground to basket pivot point allows for carefree dumping into the tallest Stripper style builders. Curtains hang down to prevent wind from blowing cotton out of Builder and helps hold cotton in place while lowering basket. Photo shows Stripper Builder and Full Chain Boll Buggy.

Big 18.4 X 26 Tire

Big single 18.4 X 26 tires gives the Boll Buggy plenty of flotation to pack the heaviest of loads out of the soggiest of fields. Single tire design allows for sharp turns without sliding tires sideways as on tandem units. Helps prevent tire problems.

Swing/Pivot Hitch

Optional swing/pivot hitch shifts buggy 72″ towards picker or stripper to receive a dump of cotton, then swings back centered behind tractor for dumping into builder.

33″ Big Lip Fold-Out Door

Moves Cotton to Center of the Builder & Eases Parking beside Builder

- The Boll Buggy’s unique Big Lip design makes pulling alongside a Module Builder a snap, saving valuable field time.

- The door automatically opens when lifting the basket, gaining an additional 33″ of dump out wall and 49″ from the basket pivot point. Cotton is easily dumped in center of Builder eliminating most cotton spills.

- Top of modules made with a Big Lip Boll Buggy are even and level, gaining more cotton per module. Module haulers love to haul Boll Buggy modules and the Gin likes to gin them.

- Big Lip folds down into basket making a safe and easy transport height of 14′ 8″.